Brother was named as the most influential brand in the CFS industry, and its 20 years of hard work and classic products have created a good story

SHANGHAI, July 24, 2025 /PRNewswire/ -- Brother was awarded the title of "2025 Industry Influential Brand" at the 14th Financial Summit and 2025 New Productivity Entrepreneur Conference held from July 16 to 17. This honor is not only a high recognition of the influence of the Brother brand in the Chinese market, but also inseparable from the 20 years of hard work of Brother (China) Commercial Co., Ltd. (hereinafter referred to as "Brother (China)"), a wholly-owned subsidiary of Brother Group in China.

Brother was named "2025 (Industry) Influential Brand" by CFS

It is the 20th anniversary of the establishment of Brother (China). Looking back on its journey, the company, with its keen market sense, has introduced many high-quality Brother products to the Chinese market, and has created several popular classic models in many fields such as office printing, logo marking, and household sewing. With twenty years of persistence and innovation, it has written a wonderful chapter of the common growth of brand and market.

Classic printing products have gone through cycles, and core technologies are widely recognized by the market

As one of the few manufacturers in the industry that possesses laser, inkjet, thermal and thermal transfer printing technologies, Brother's printing products continue to win the trust of consumers with key core technologies and innovative functional services. Once launched, many models continue to refresh the market's imagination of the performance of printing equipment.

In the early 20th century, fax was the main means of file transmission. Although Brother entered the market relatively late, it gradually opened up the market for this category with its two fax machines, FAX-218 and FAX-728, and its brand strength was beginning to show.

Combining its own technology and experience, Brother introduced the concept of "MFC" (multi-function all-in-one machine, integrating printing, copying, faxing and scanning) in the industry, and was one of the first to realize the application of "drum-to-powder separation" technology in the field of laser printing. This technology modularizes the drum and toner cartridge, allowing users to replace toner separately as needed, reducing printing costs while reducing environmental load, which is especially suitable for office scenarios with large printing volumes. The MFC-7340 and DCP-7180DN are classics equipped with this technology.

From left to right: MFC-7340, DCP-7180DN, DCP-C421W

The MFC-7340, launched in 2008, is Brother's classic 4-in-1 black-and-white laser multifunction printer. During its sales period, it once ranked among the top three in the laser 4-in-1 market*1. The DCP-7180DN was the first to propose "printing 10,000 pages without paper jam" as early as 2014, and invited a notary office to notarize the test at the launch conference, boosting channel confidence with its hard-core quality. Its sales performance remains strong to this day, with cumulative sales in China exceeding 1.2 million units.

In the field of inkjet printing, Brother's first rechargeable product DCP-C421W was widely reported as soon as it was unveiled during the fifth CIIE. This product adopts the service concept of "print on demand, pay by page", and only needs to pay according to the actual number of printed pages in the later stage. Consumables are provided by the official, which saves users from the procurement dilemma of "difficult selection, tiring price comparison, and difficulty in distinguishing between true and false". This product has won the "GOOD FOCUS AWARD [NEW BUSINESS DESIGN]" award from the well-known design award "Good Design Award" in recognition of its outstanding contribution to business model innovation. This business model is also used in the latest cloud charging series laser printers HL-10W and DCP-11W, reducing the entrepreneurial burden for small entrepreneurs.

Label printing products amaze the market, and multiple application scenarios open up growth space

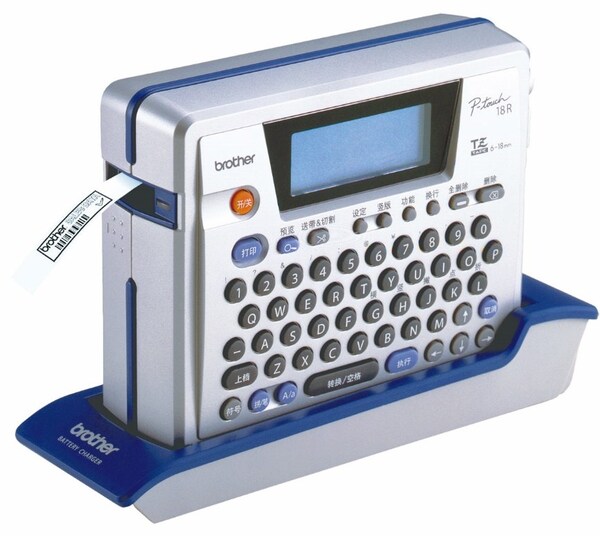

Brother label printers also demonstrate long-term vitality in the Chinese market. The classic model PT-18R has set a 21-year best-seller record and continues to be sold today, becoming a rare "evergreen" product in the industry.

PT-18R

The ultimate refinement of user experience makes the PT-18R have many highlights in details: it is Brother's first vertical label printer with a keyboard, and also Brother's first 18mm label printer with a standard automatic full-cutter; it uses nickel-zinc rechargeable batteries and a dedicated charging base to replace the popular dry battery power supply method at the time, which is more energy-saving and environmentally friendly; through the P-touch Editor software, it can be directly connected to the computer database to efficiently complete large-scale label printing; users can also incorporate company logos and other graphics into the label design to accurately adapt to the personalized needs of different companies.

PT-18R is also compatible with Brother TZe coated ribbons, which are resistant to wear, water, corrosion, high and low temperature, strong adhesion, and fading. The "six resistance characteristics" of the ribbon are more valuable in extreme use environments. Back then, with this technical advantage, Brother label printers successfully expanded to domestic medical, manufacturing, retail and other industries, shaping its good reputation in the field of label printing.

Deeply integrated into home and commercial scenarios, sewing and embroidery products set off a trend of personalization

Today, personalized customization has become one of the strong driving forces for consumption growth. Since the introduction of the first Brother sewing and embroidery machine, Brother (China) has seen the potential of customized demand to reshape the domestic consumption pattern in the future, and is committed to breaking the stereotype that "sewing machines are equal to repair tools" and promoting the industry into the "creative productivity era".

From left to right: NV180, M370, PR680W

Brother's first all-in-one sewing and embroidery machine to enter the Chinese market, the NV950, became a popular sewing product on the e-commerce platform that year with its two-in-one functional advantage; and the NV180 was later equipped with touch buttons and a color touch screen, further improving the user experience; the M370 added a wireless transmission function for embroidery data compared to the previous generation, and launched the "Enjoy Embroidery" APP adapted for Chinese users, allowing personalized customization services to be easily integrated into personal life.

The PR series of commercial embroidery machines is another proof of Brother's outstanding customization capabilities. The series was originally positioned to serve factory-type customers, and it set off an industry innovation with its subversive design of "factory-level output efficiency and home-level operation experience". After years of iteration, the PR series models currently on sale are equipped with many convenient functions such as "wireless transmission", "my design center", "cross camera positioning", etc., and the service scenarios have also expanded from personal studios to retail stores, and continue to penetrate the market.

Offices, factories, stores, homes... After 20 years of hard work, Brother products have been deeply integrated into China's diverse scenarios, winning the market's high recognition of the brand's strength. In the future, Brother (China) will adhere to the concept of "In China, For China", continue to strengthen innovation investment, and create more high-quality and innovative products for Chinese users.

Note: *1 Data is from 2009 and 2010 IDC industry reports